Partnering with Struers

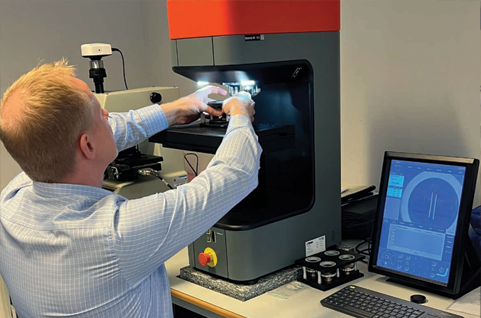

Struers is dedicated to pursuing deep scientific insights and developing groundbreaking technologies.

We continue to deliver more innovative solutions and products, such as One Partnership, that enable your team to excel and face the future with confidence. Our team understands that it is vital your business maintains the highest standards of performance and quality. That’s why you need a partner who is ready to support every stage of your preparation process – far into the future – with fast, accurate, safe, and efficient results you can rely on.

Contact Us Today