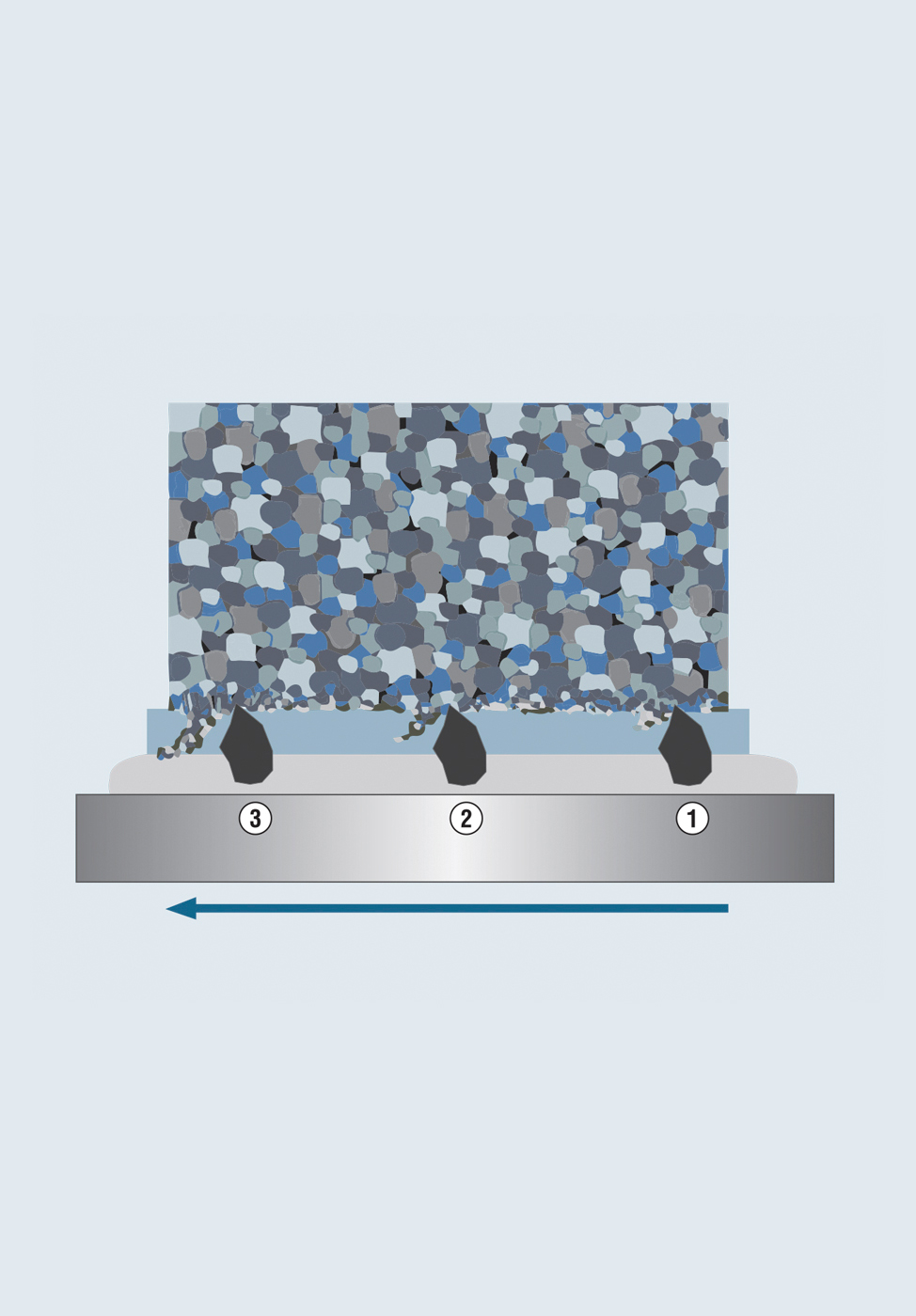

Specimens are thinned by a variety of methods including:

- Mechanical cutting and grinding (used in the preliminary steps of sample preparation)

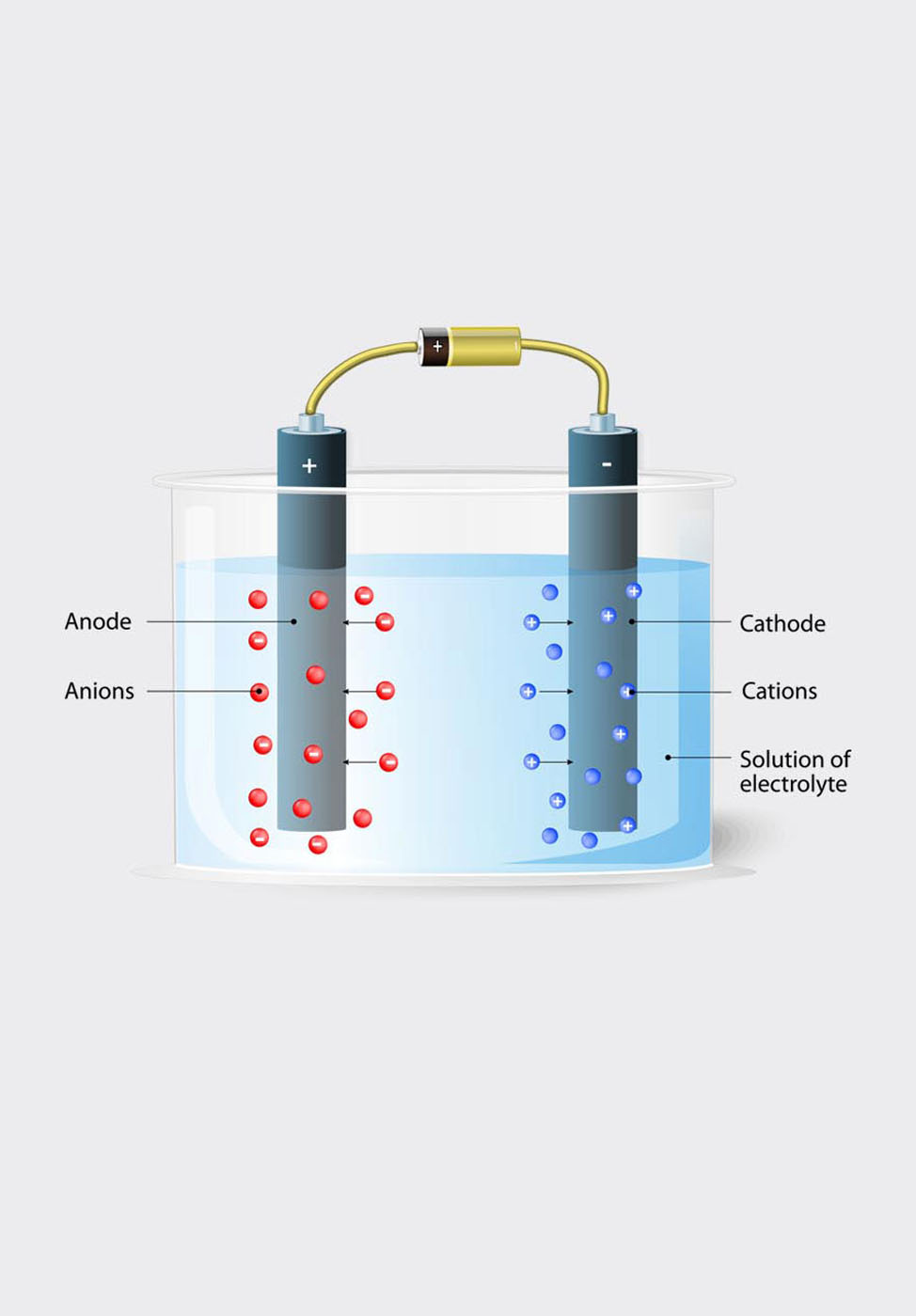

- Electrolytic polishing (commonly used for final thinning of metals)

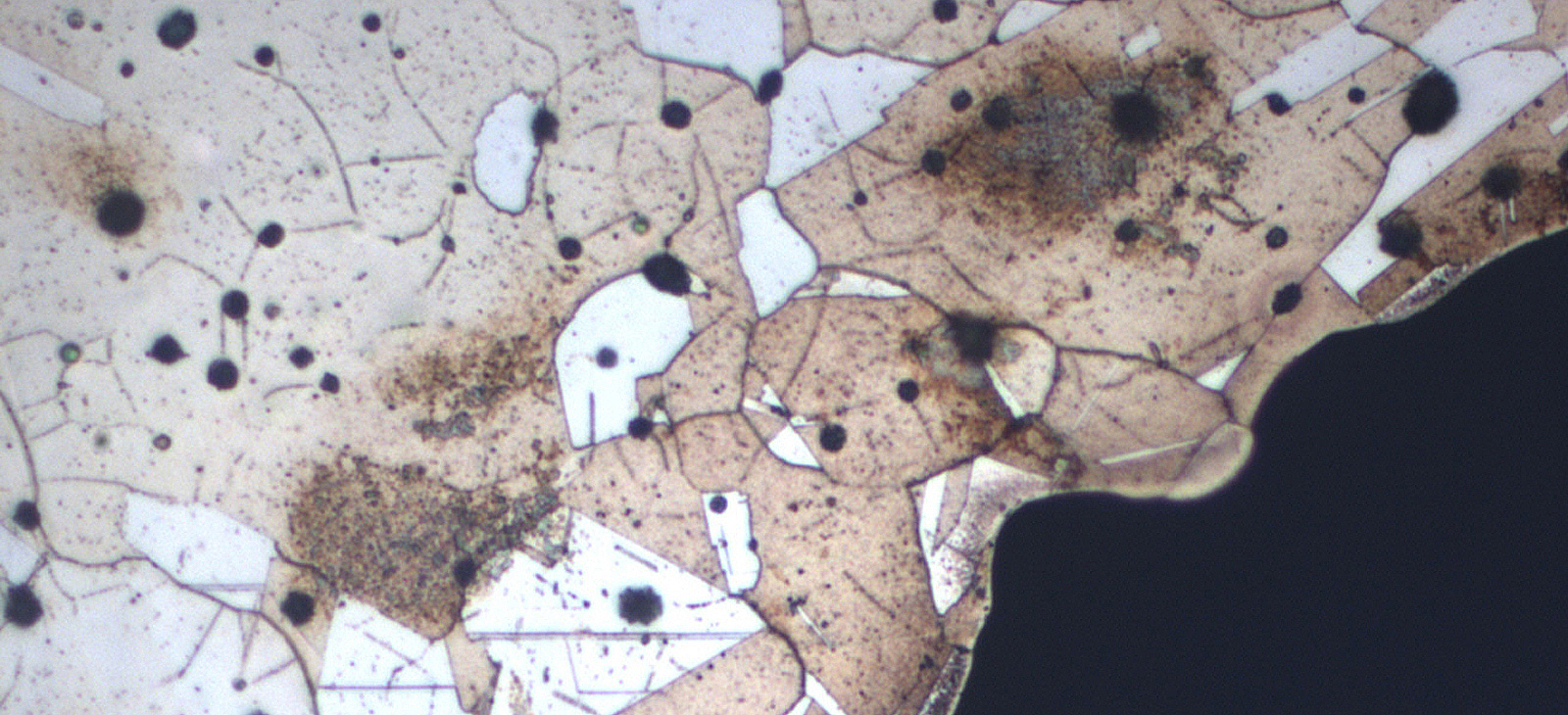

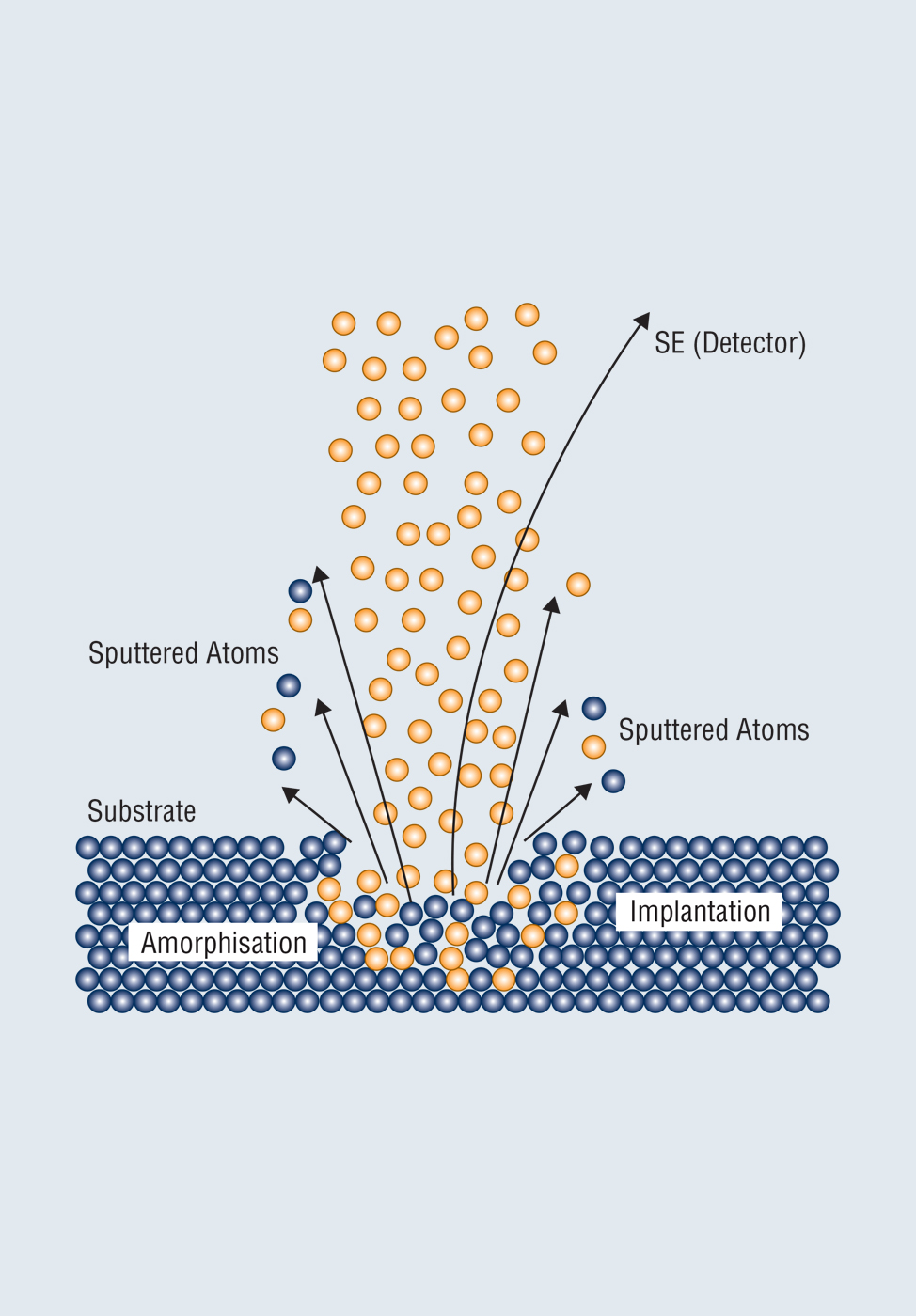

- Ion milling (used with both metals and insulating materials)

It is crucial that any damaged layer introduced during preliminary mechanical preparation is fully removed during subsequent electropolishing or ion milling.

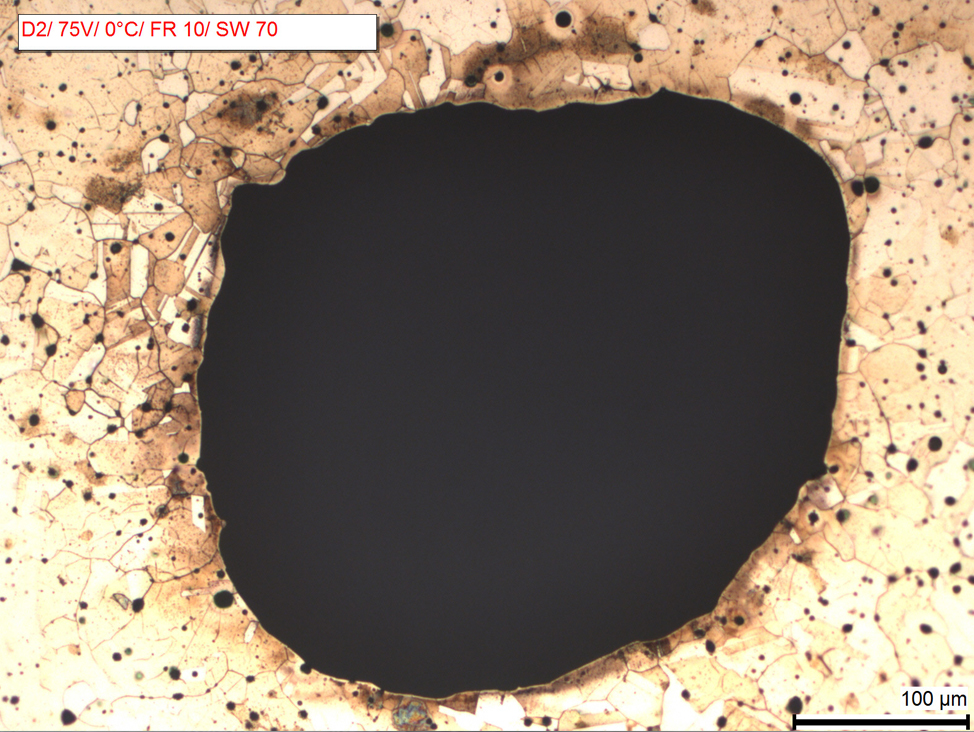

Final thinning is continued until a hole first forms near the center of the disk; then the electropolishing or ion milling processes are immediately halted. The thin tapered portions of material adjacent to the hole are frequently thin enough to be electron transparent.

If electropolishing or ion milling are continued too long, the thin electron transparent sections adjacent to the hole will be removed, and the remaining material may be too thick to be penetrated by the electron beam.