AbraPol-30 facts

- High capacity for large specimens

- Powerful and fast preparation

- Adjustable dosing units

- User-friendly interface and design

- Controlled material removal

- Method database

- Easy method creation

- Maximum operator safety

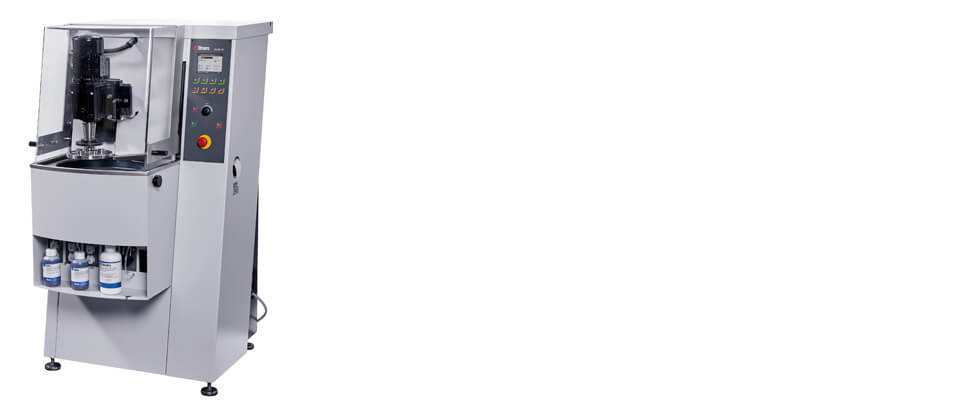

AbraPol-30 is an advanced, semi-automatic machine for grinding and polishing of specimens in specimen holders. Double dosing of diamond suspensions and lubricants ensures best distribution and thus an optimal utilization of the consumables. AbraPol-30 is designed for laboratories or workplaces carrying out testing of large specimens or a high volume of specimens.

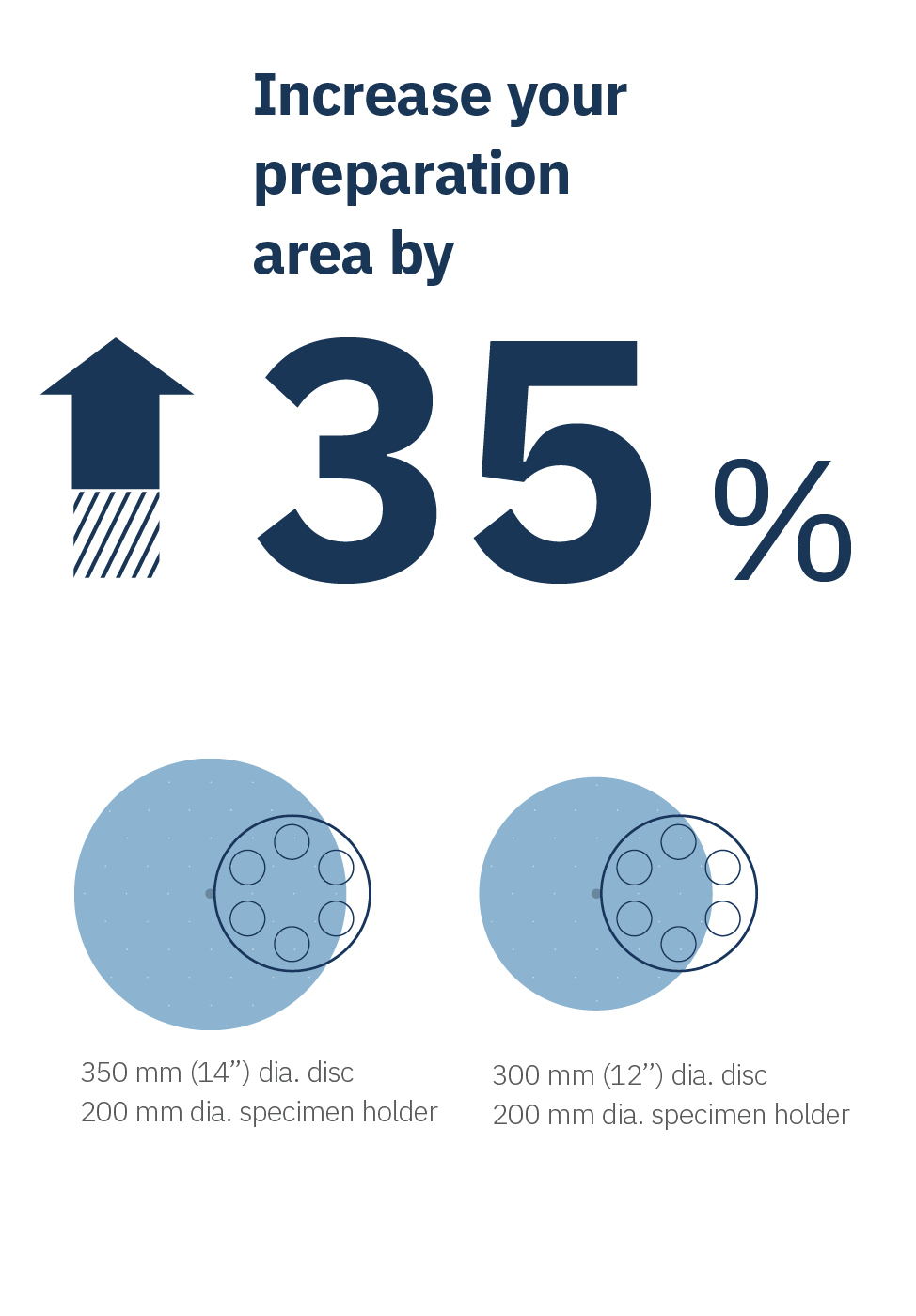

Optimize your preparation area

AbraPol is ideal for laboratories or workplaces that prepare large samples and/or a high volume of specimens. You can upgrade your disc size from 300 mm (12’’) in diameter to 350 mm (14’’) for greater efficiency when working with large or multiple samples. For best results, we recommend combining a 350 mm (14’’) disc with a 200 mm diameter specimen holder – which will increase your preparation area by up to 35%.

Maximize throughput and efficiency

AbraPol’s unique double-dosing feature ensures the best distribution of suspensions and lubricants on large preparation surfaces, for the optimal utilization of your consumables. When double dosing and a 350 mm (14”) disc are combined, you get the best possible distribution on the polishing surface – maximizing throughput and efficiency.

With up to 600 rpm on the surface and 300 rpm on the specimen mover, AbraPol also helps you to increase throughput by speeding up the grinding and polishing process. In addition, controlled and accurate material removal allows you to preset stock removal, which saves further time.

Reliable, valid results

AbraPol has an extremely solid frame and powerful motors to give you outstanding reproducibility and reliability of results. And, to ensure you can work all day with large and heavy specimen holders, it has a unique design that reduces vibration.

To enable operators to get started right away, AbraPol includes 10 Struers Metalog Guide methods, covering all major material groups. In addition, AbraPol includes a method database capable of storing up to 200 preparation methods.

KEY FUNCTIONS THAT ENSURE HIGH-VOLUME GRINDING AND POLISHING IN THE LAB OR IN THE PRODUCTION HALL

-

Double-dosing lowers consumables consumption

AbraPol is designed for both 300 and 350 mm (12” / 14”) diameter discs. To ensure the best distribution of suspensions and lubricants, these are dosed via two dosing nozzles. The DP-Pump unit contains two pumps, one for each dosing nozzle, to ensure equal dosing from both nozzles.

When combined with a 350 mm (14”) disc, double-dosing gives you the best possible distribution on the polishing surface. This can reduce surface wear by up to 70%, lowering your consumption of consumables.Double-dosing lowers consumables consumption

-

Up to 6 individual pump units

AbraPol can be equipped with up to six individual pump units to cover all requirements. This can be six DP-Pump units or a combination of DP-Pump units and up to 2 OP-Pump units.

The OP-Pump unit is specially designed so the tubes are cleaned with water after end preparation, which avoids clogging of tubes and nozzles.Up to 6 individual pump units

-

Stainless steel bowl for improved lifetime

Made from high-quality stainless steel, AbraPol’s bowl is less likely to be damaged if a specimen is lost at high speed, reducing maintenance requirements and increasing safety. The bowl comes with a lifetime corrosion warranty on breakthrough corrosion.

A special AbraPol disposable bowl liner is also available for easy cleaning.Stainless steel bowl for improved lifetime

-

Non-clogging outlet stops blockages

The AbraPol has a large (50 mm / 2" diameter) outlet and a drain tube with a smooth inner surface to ensure that grinding water does not clog the bowl. The bowl’s outlet can easily be cleaned using a brush or ‘bottle-brush’ without pushing the drain tube away from the outlet.

Non-clogging outlet stops blockages

-

Removal rate sensor for a more accurate process

AbraPol’s built-in removal sensor ensures precise material removal no matter your material.

When using time to measure material removal, there is a risk of too much or too little material being removed, especially when working with very small or very large/hard specimens. Measuring material removal instead will ensure you only remove the material required, saving you time in the next process step.Removal rate sensor for a more accurate process

-

Recirculation unit for cost-efficient water use

Cooling water minimizes heat when grinding. The AbraPol’s integrated recirculation cooling water unit ensures cost-efficient water utilization and collects removed abrasives to lower your water consumption and reduce the amount of classified products spent.

The unit is easy to access for maintenance and cooling water control. For improved safety, the three-phase recirculation pump is connected directly to the AbraPol machine to ensure the emergency stop also stops the recirculation pump.Recirculation unit for cost-efficient water use

-

Vary rotational speed for careful or fast preparation

On the AbraPol, the rotational speeds of both the disc and the specimen holder can be adjusted for either very careful or very fast preparation.

The disc speed can be set from 40 – 600 rpm; specimen holder speed from 50 - 300 rpm.Vary rotational speed for careful or fast preparation

-

Strong safety cover for operator safety

AbraPol has a strong transparent safety cover for maximum operator safety. The safety cover keeps fumes inside the machine and reduces noise.

In manual mode, the preparation disc can rotate without the safety cover locked. However, in semi-automatic mode, the machine can only be started when the cover is closed; the cover can only be opened again once the machine has stopped completely. The machine also includes an emergency stop, which stops all machine functions.Strong safety cover for operator safety

-

External fume extraction for greater safety

To improve the working environment, AbraPol can be connected to an external exhaust system via the built-in exhaust tube. This ensures the safe extraction of fumes, such as from alcohol-based consumables.

External fume extraction for greater safety

-

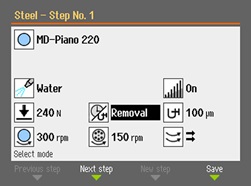

User-friendly interface for minimal training

AbraPol is easy to operate, making extensive training unnecessary. A large and clear display with large icons gives the operator a perfect overview of process parameters. The multipurpose turn/push knob makes navigation easy. The countdown feature allows the operator to see the remaining preparation time or remaining material removal.

User-friendly interface for minimal training

-

Beacon for monitoring from across the lab

The colored beacon on AbraPol enables the operator to monitor the machine’s operating state from a distance. The different colored lamps on the beacon can be set up individually to give the operator specific status information as required.

Beacon for monitoring from across the lab

-

DP-Pump unit calibration for high reproducibility

AbraPol helps you increase the reproducibility of your preparation results by ensuring equal dosing of suspensions and lubricants. To lower the dosing tolerances, AbraPol’s DP-Pump units can be calibrated using a special calibration procedure included in the software.

DP-Pump unit calibration for high reproducibility

Facts

Model types

Precise and powerful performance

AbraPol-30

Advanced semi-automatic machine for grinding and polishing of specimens in specimen holders up to 200 mm/8” dia. A removal rate sensor and a transparent safety cover are included. Suspension/lubricant and oxide suspension pump units, recirculation cooling tank, pump and filter, grinding/polishing discs, and specimen holders are available separately.

AbraPol-30 with shift valve

AbraPol-30 with shift valve

Advanced semi-automatic machine for grinding and polishing of specimens in specimen holders up to 200 mm/8” dia. A removal rate sensor, a transparent safety cover, and a shift valve for recirculation or drain are included. Suspension/lubricant and oxide suspension pump units, recirculation cooling tank, pump and filter, grinding/polishing discs, and specimen holders are available separately.

Struers’ equipment conforms with the provisions of the applicable International Directives and their appurtenant Standards. Struers’ products are subject to constant product development. Thus, we reserve the right to introduce changes in our products without notice.

Technical Data

AbraPol-30 Technical Data Sheet

Struers Technical Data Sheets are designed to help you make the best choice of equipment for your particular purpose. You can find important information such as capacity and performance specifications, dimensions, weight, electrical data, noise levels, ambient conditions, and safety. In many cases you can also obtain an overview of accessories offering higher capacity and performance.

Download Technical Data SheetPerfectly reproducible

Download our AbraPol brochure to get a full overview of this grinding & polishing equipment.

Download the brochureFind the right accessories for your AbraPol

Increase the efficiency of your process and improve the reliability of your result with our grinding and polishing accessories. We offer a full range of specimen holders, mover plates, leveling devices, and preparation discs.

Download our accessories overview sheetGrinding & Polishing consumables

-

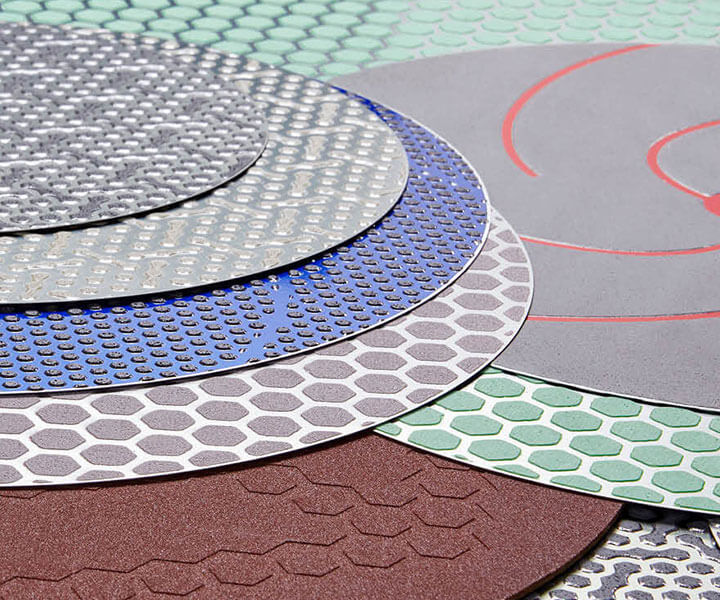

MD Grinding

For plane and fine grinding with virtually no artifacts

Read more Contact sales -

Silicon Carbide Foil and Paper

For plane and fine grinding

Read more Contact sales -

Diamond Pads

For plane and fine grinding of very hard materials

Read more Contact sales -

Polishing cloths

For any material and preparation goal

Read more Contact sales -

DiaPro

All-in-one diamond solution optimized for a specific polishing cloth

Read more Contact sales -

DiaDuo-2

All-in-one diamond solution

Read more Contact sales -

DP-Products

Diamond suspensions in a wide variety of grain sizes and formats

Read more Contact sales -

DP-Lubricants

For accurate cooling and lubrication while polishing

Read more Contact sales -

Oxide Polishing

When no scratches and deformation is required

Read more Contact sales -

+

-

−

Correct preparation solutions

"True structures require proper and correct applications. Different material properties require broad application knowledge. Struers application specialists are experts in optimizing preparation methods, because application knowledge is necessary to select the correct preparation solutions. Your material – our application solutions.”

Birgitte Nielsen

Application Specialist, Struers ApS

MEET SOME OF OUR CUSTOMERS

Don’t make do with what we say! Look for the truth in the experiences of the people who use our equipment and knowledge. We asked a few of our loyal customers to tell us what they think is most important about Struers.

We are extremely satisfied with the highly skilled service delivered by Struers. They always meet our needs quickly and efficiently.BRP Powertrain GmbH & Co. KG (Austria) Herr Thomas Brunmair Supervisor Material Lab

We have been using Struers equipment and consumables for almost 30 years and have benefitted enormously from their unparalleled service and applications support.John Crane UK Ltd. UK Bill Taylor Materials & Forensics Engineer

My relationship with Struers dates back over many years. The reason is their expert advice, good service, and their use of our application laboratory in the case of difficult questions that are best resolved on-site.WWU Münster, Institut für Planetologie Ursula Heitmann Mineral Specimen Preparer