Cast Iron Specimen Preparation

This guide will enhance your metallographic preparation for Cast Iron. The main challenges in metallographic preparation of cast iron is to maintain the true shape and size of the graphite in its flake, nodular or tempered form. In grey irons, the carbon is present as graphite; in white cast iron, it is present in the form of iron carbide and alloy carbides.

The shape of the graphite has a significant influence on the mechanical properties of cast iron, metallographic quality control of grey iron is an integral part of the cast iron production process.

The metallographic quality control process for cast iron is:

- Assessing graphite size and distribution on an unetched, polished specimens using standard reference charts or image analysis.

- Etching the specimens to examine matrix structure, depending on specifications.

An interesting fact is that graphite is actually three-dimensional, even though perceived as two-dimensional.

How to retain the graphite in its original shape and size?

A common preparation error is the insufficient removal of smeared matrix metal after grinding, which can obscure graphite’s true shape and size. This is particularly seen with ferritic and austenitic cast irons, which are prone to deformation and scratching. To address this, a thorough diamond and final polish is essential. Verification to show that carbon is completely retained by using a higher magnification than 100x.

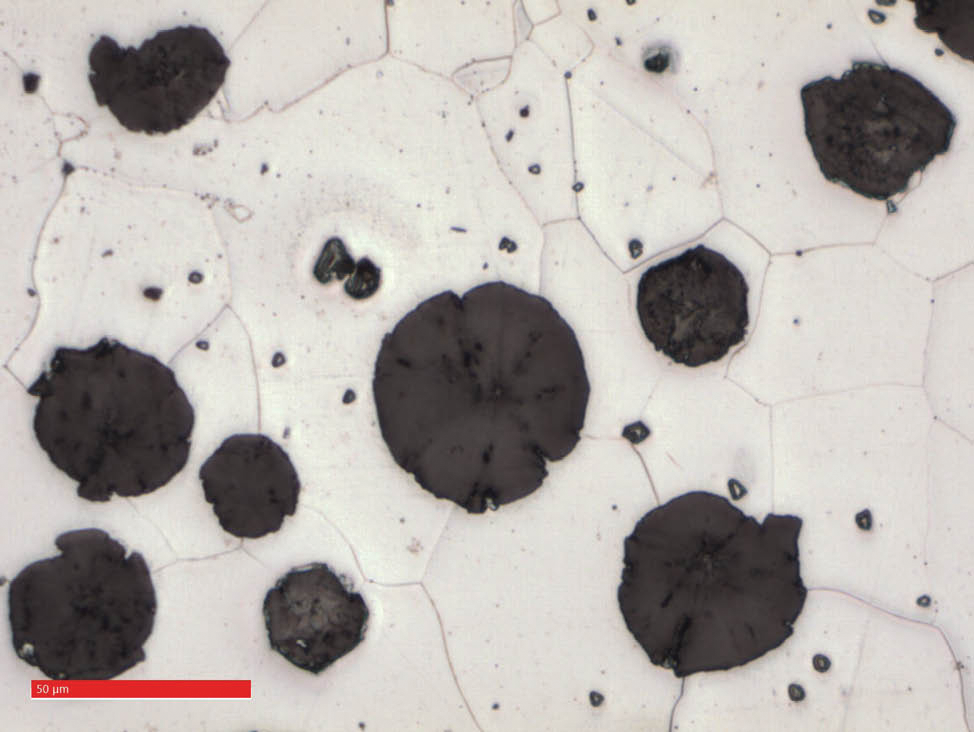

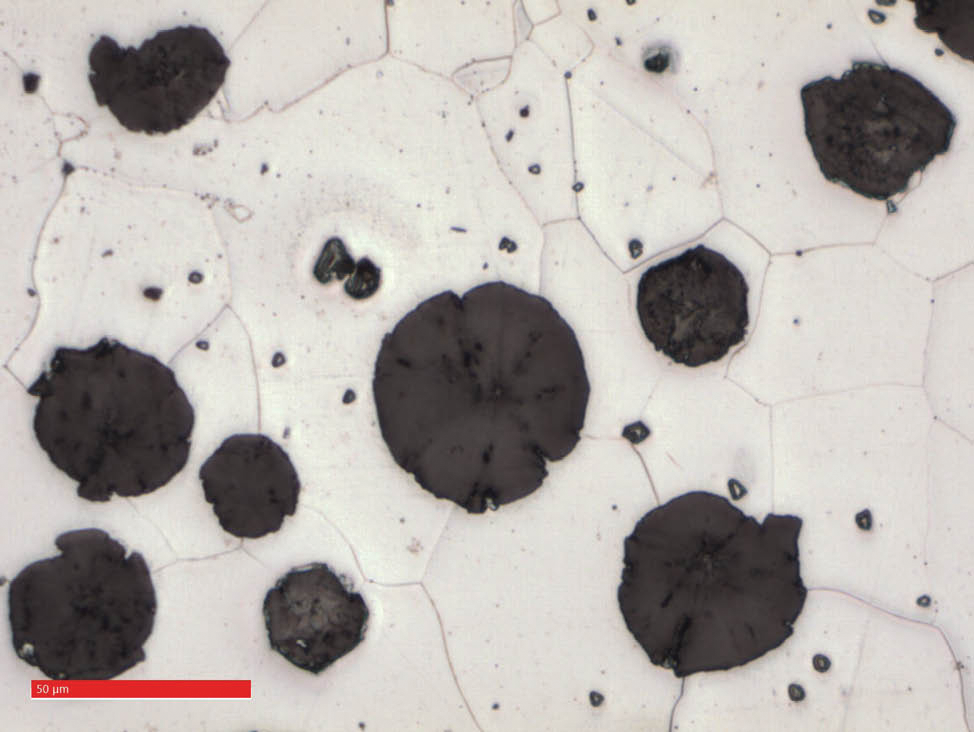

Did you know well polished graphite is grey not black? See figure 1.

Fig 1. It appears black when viewed with a lower magnification as shown in the below image, of Ferritic cast iron with spheroidal graphite, etched with Nital.

Fig 1. It appears black when viewed with a lower magnification as shown in the below image, of Ferritic cast iron with spheroidal graphite, etched with Nital.

The carbon is primarily present as graphite in a spherical form. The spherical form results in improved strength in comparison to lamellar cast iron, but the hardness of the material is lower due to the lack of cementite in the purely ferritic matrix.

Image taken with Zeiss Smartzoom 5, at approx. 500x magnification.

The challenges associated with the preparation of cast irons with graphite can be compounded in situations where metallography is an integral part of the casting line quality system with limited time constraints. Understanding and overcoming this difficulties will assist your Foundry to get consistent results.

Cast Iron Solution:

- Cutting stage – a cubic boron nitride wheel is recommended, and if you are cutting larger sections, an automatic process is more efficient than a manual.

- Mounting – Often, foundries will use unmounted specimens, and with a sample holder, you can bolt your specimens for the grinding and polishing stages – preparing up to 6 samples at a time.

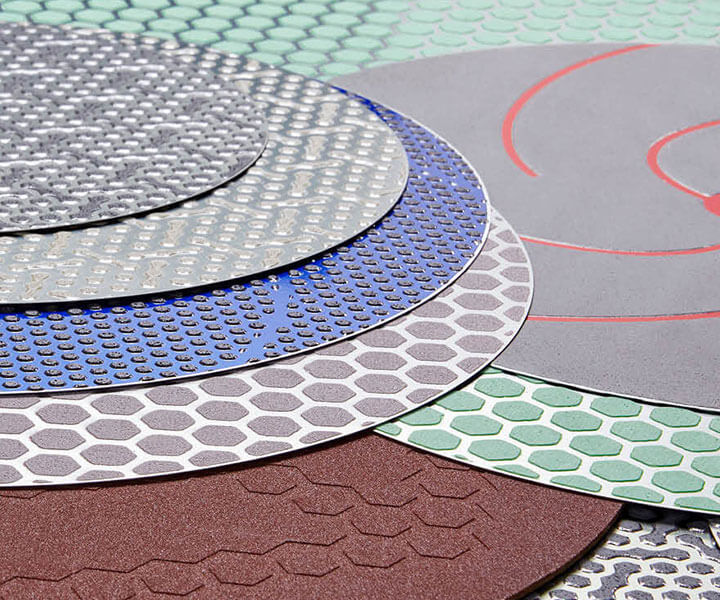

- Grinding and Polishing Steps – Use a diamond grinding surface and complete a thorough diamond polishing using hard polishing surfaces and include a final oxide polishing step.

Fig 2. Grey iron prepared with fine grinding using diamond surface shows good edge retention that can be gained by streamlining preparation methods.

Fig 2. Grey iron prepared with fine grinding using diamond surface shows good edge retention that can be gained by streamlining preparation methods.

Grinding and Polishing Cast Iron Samples

Select the right surface to reduce deformation:

- Hard white cast irons and ADI irons Struers recommend to use a diamond surface such as MD-Piano 220 and also fine ground with diamond MD-Allegro.

- Soft and medium hard cast irons with a ferritic, austenitic or pearlitic matrix are plane ground with silicon carbide Foil/Paper and fine ground with an MD-Largo.

- Cast irons that corrode whilst polishing it is recommended to use water free diamond suspension, A, and yellow lubricant.

Struers 4-step method for white cast irons uses Struers MD surfaces; these ensures uniform material removal with no smearing in soft phases or chipping in brittle phases.

Step One -MD-Piano 220,

Step Two - the fine grinding step with MD-Allegro combined with DiaPro Allegro/Largo 9.

Step Three - MD-Dac with DiaPro 3

Step Four - MD-Nap DiaPro Nap B1.

After the first step the fine grinding and polishing should be completed in 10 minutes if your techniques are taking longer try the above recommended methods for quicker consistent results, view all the polishing times and force details.

Cast irons with graphite can be prepared in 3-steps and in 11 minutes, although many laboratory technicians prefer to add in an OP-Chem step for one minute at the end.

Discover more comprehensive information on cast iron