With the Duramin-40, we can take before and after pictures easily, so we can see potential cracks before we start the tests – and analyze them more efficiently afterwards.Everllence Jesper Vejlø Carstensen Senior Research Engineer, M.Sc., Ph.D.

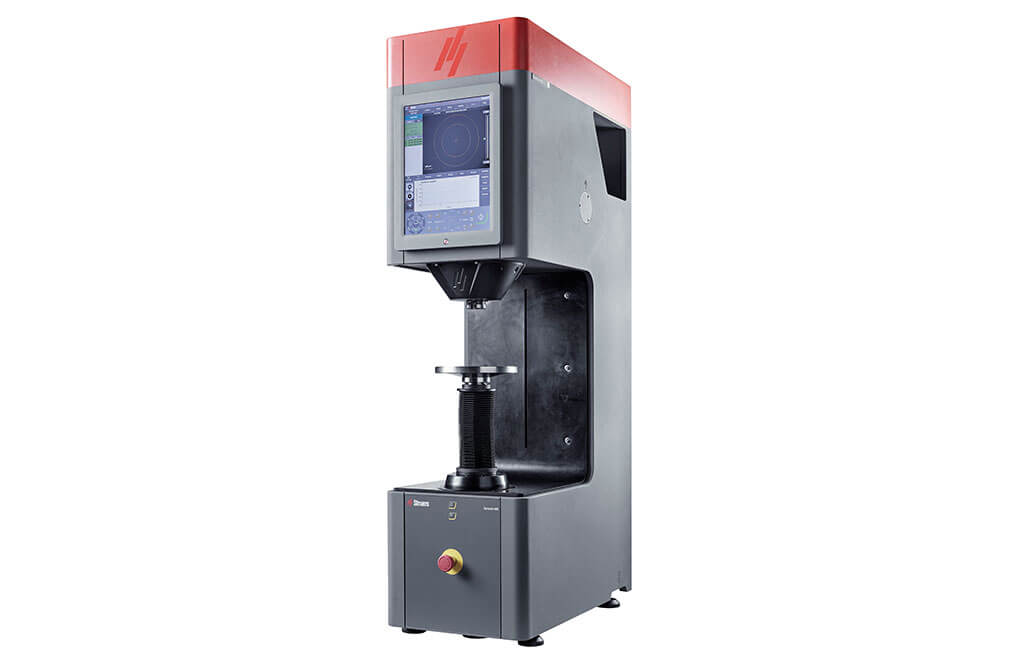

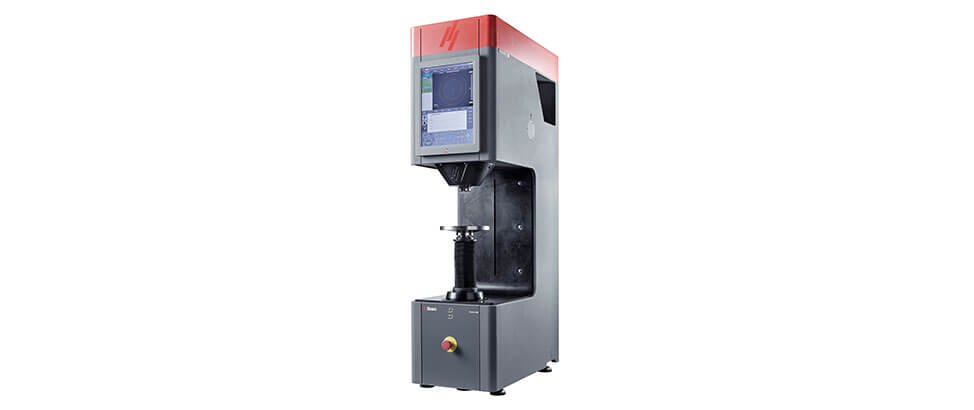

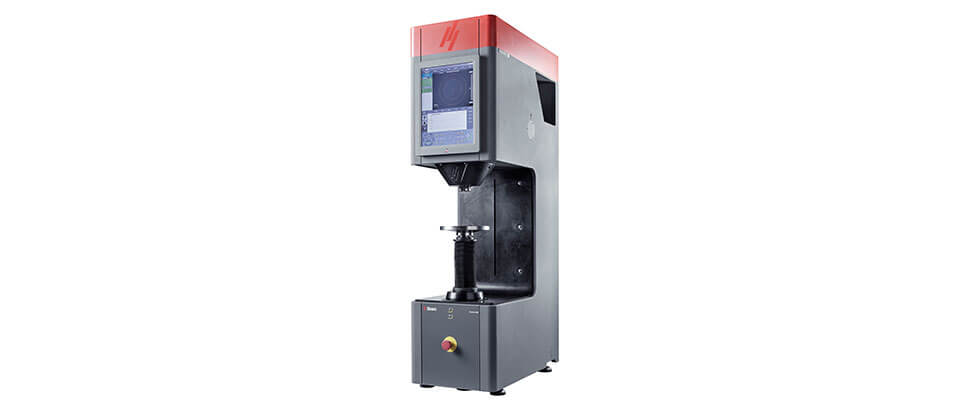

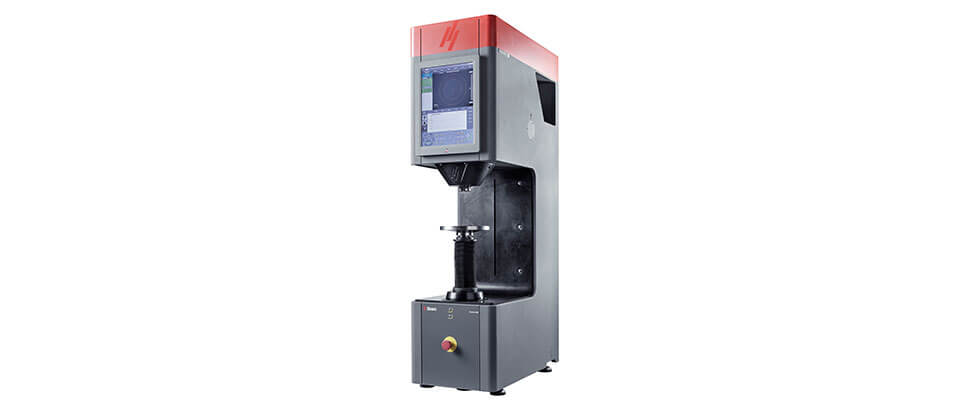

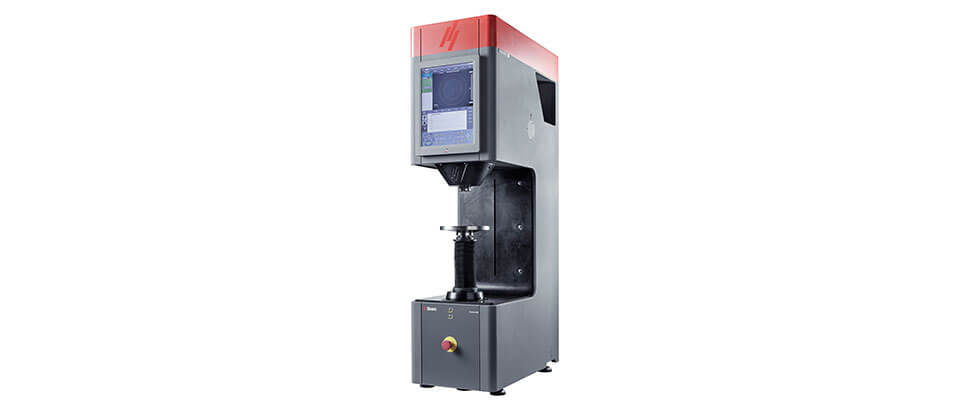

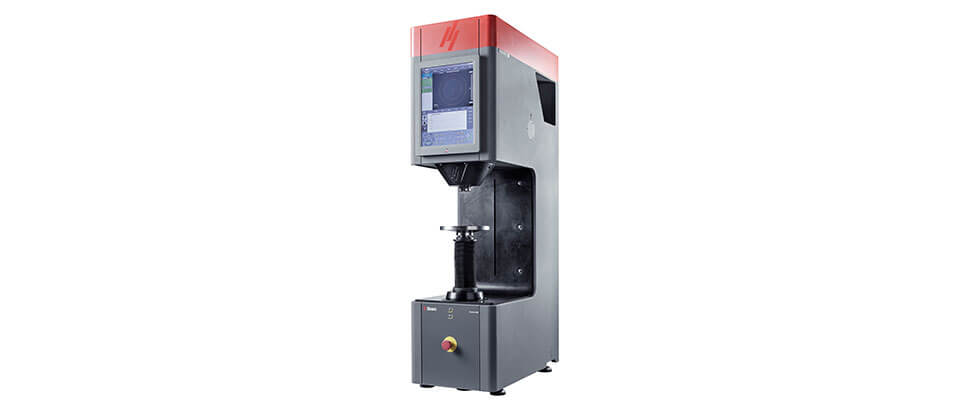

Duramin-600 is designed to survive the toughest production environment. It is a universal hardness tester, operated by a robust touchscreen, and comes available in three load ranges and with an optional motorized Z-table for larger samples.

Designed to last, the Duramin-600 employs industry strength components from the 400 kg frame to the display.

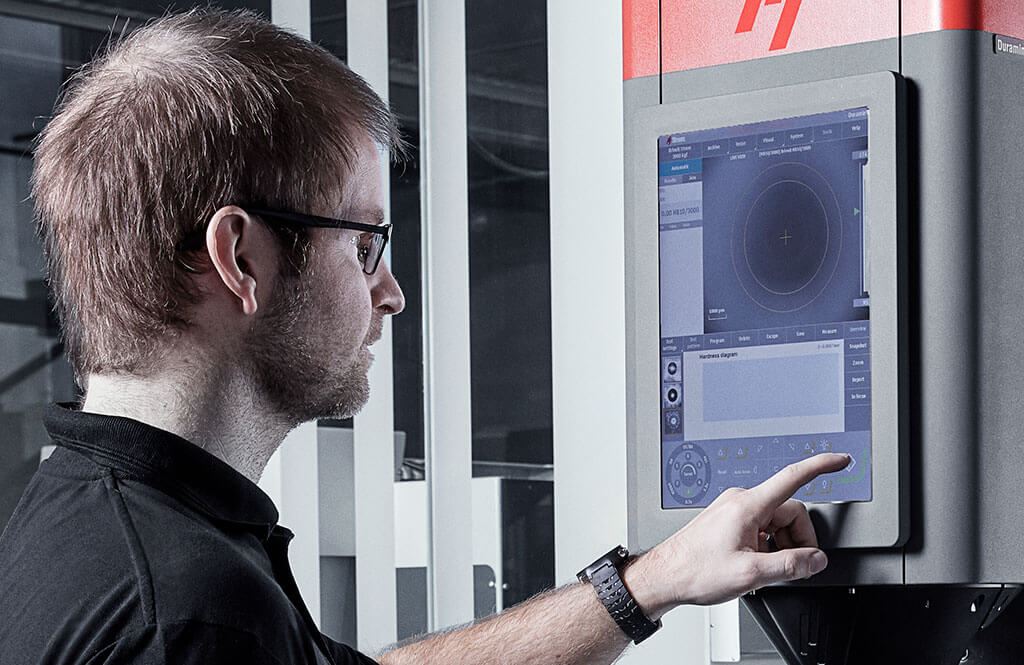

Simple clamping, combined with clean software and a touchscreen, ensure stress-free operating and result reporting.

The accurate and repeatable loading system based on load cell technology, combined with advanced software algorithms, ensures specific and repeatable image and hardness evaluation.

Duramin-600 is available with a six-position automatic turret, facilitating exchange of up to three indenters and three objective lenses. The exchange of indenter and lens runs fully automatically in each model, helping to avoid calibration and potential human errors.

Duramin-600 is available with an optional motorized spindle. This avoids the repetitive manual adjustment of the test anvil.

The Duramin-600 is built using a rigid metal frame that is ideal for rough conditions.

A variety of clamping devices and fixtures are available.

Duramin-600 is operated from a large 15-inch color touchscreen.

Measurement data can be exported in various formats and saved on a USB stick or network.

Test reports and measurement data can be easily generated and exported.

The machine automatically stops in the event of a work piece collision or any unexpected vibration or movement. This prevents damage to indenters and secures safety for operators.

The Duramin-600 models come with a motorized, six-position turret, automatic illumination adjustment, auto focus, and automatic image evaluation as standard. The maximum sample height is 330 mm, with a throat depth of 260 mm. Duramin-600 is operated via a 15-inch color touchscreen. Objective lenses and indenters are ordered separately. All Duramin-600 M models come with manual Z-axis adjustment. All Duramin-600 Z models come with a motorized Z-axis adjustment.

Struers’ equipment is in conformity with the provisions of the applicable international directives and their appurtenant standards. Struers’ products are subject to constant product development. Therefore, we reserve the right to introduce changes to our products without notice.

Struers Technical Data Sheets are designed to help you make the best choice of equipment for your particular purpose. You can find important information such as capacity and performance specifications, dimensions, weight, electrical data, noise levels, ambient conditions, and safety. In many cases you can also obtain an overview of accessories offering higher capacity and performance.

Download Technical data sheetGet the full introduction, descriptive visuals, and key feature descriptions to help you qualify your choice of equipment.

• Explanatory fotos

• Key feature descriptions

• Technical Data Sheet

"True structures require proper and correct applications. Different material properties require broad application knowledge. Struers application specialists are experts in optimizing preparation methods, because application knowledge is necessary to select the correct preparation solutions. Your material – our application solutions.”

Birgitte Nielsen

Application Specialist, Struers ApS

Don’t make do with what we say! Look for the truth in the experiences of the people who use our equipment and knowledge. We asked a few of our loyal customers to tell us what they think is most important about Struers.

With the Duramin-40, we can take before and after pictures easily, so we can see potential cracks before we start the tests – and analyze them more efficiently afterwards.Everllence Jesper Vejlø Carstensen Senior Research Engineer, M.Sc., Ph.D.

We are extremely satisfied with the highly skilled service delivered by Struers. They always meet our needs quickly and efficiently.BRP Powertrain GmbH & Co. KG (Austria) Herr Thomas Brunmair Supervisor Material Lab

Since adopting Struers equipment, we have made significant savings within our manufacturing process as a result of reduced manpower requirements and productivity improvements.Nissan Motor Manufacturing UK Ltd. John Smart Production Supervisor