With the Duramin-40, we can take before and after pictures easily, so we can see potential cracks before we start the tests – and analyze them more efficiently afterwards.Everllence Jesper Vejlø Carstensen Senior Research Engineer, M.Sc., Ph.D.

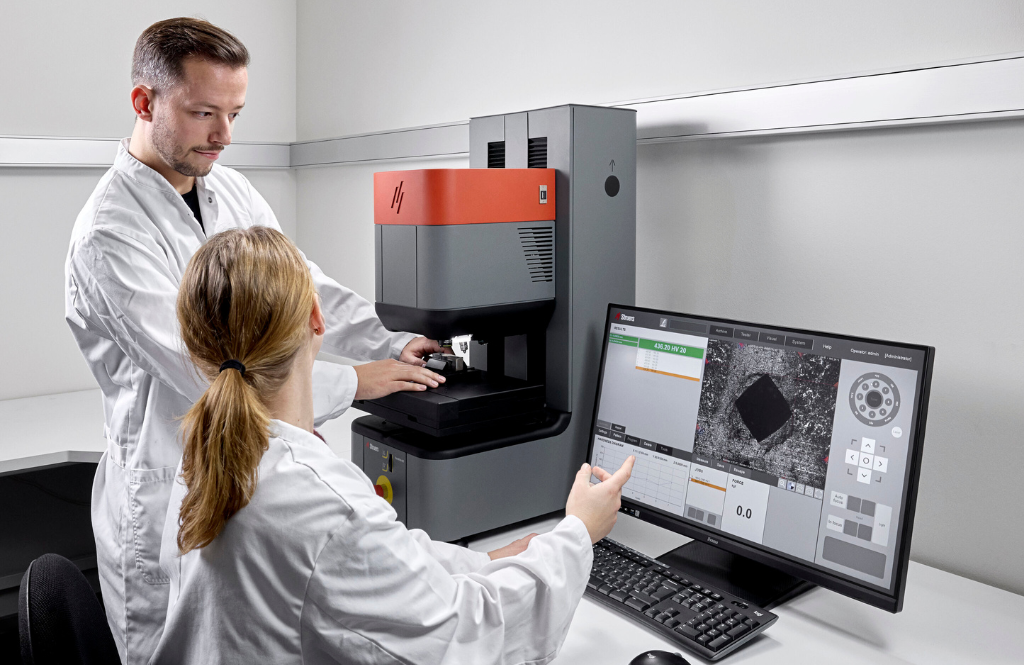

The DuraVista-80 is a top-tier automated micro hardness tester, supporting Vickers, Knoop, and Brinell scales from 0.1 gf to 62.5 kg. Its advanced movable test head features an 8-position angled turret for improved versatility and ergonomic use, while closed-loop loadcell technology and precision optics deliver consistent, reliable measurements.

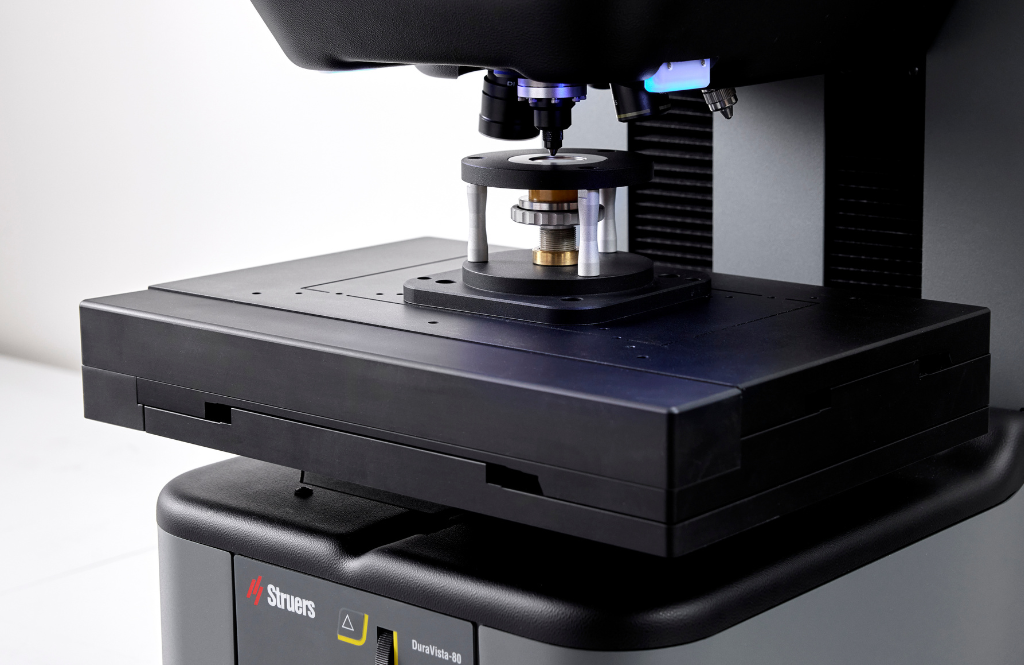

The DuraVista-80 stands out with its movable test head, designed to quickly position the load system and optics at the desired location. Utilizing a dual displacement system ensures precision by employing a separate high-precision load motor for test loads.

The Twin model, DuraVista-80T, elevates versatility with an integrated test table spindle. This enables effortless positioning of your samples at an ergonomic height and delivers unparalleled flexibility.

Our advanced touch focus technology, featuring a dedicated probe delivers fast and reliable auto-focus from extended distances. Designed for consistent performance, it ensures operator independence and exceptional repeatability.

Experience unmatched versatility with the innovative 8-position turret, a masterpiece of high-quality mechanical engineering. Its angled design provides full access and enhanced visibility for your samples. Each indenter position supports Vickers, Knoop, or Brinell indenters and is fully field-exchangeable for maximum adaptability.

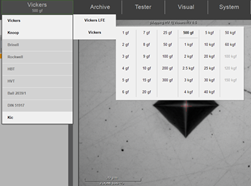

The unique, configurable test load range from 0.1 gf to 62,5 kg (0.00981 N to 612.9 N) can cover many applications that usually require both a micro- and a macro-indentation hardness tester. It also unveils new areas of interest with its sub-micro loads. It covers many Brinell, Vickers, and Knoop test methods and can automatically convert hardness values according to current standards.

The DuraVista-40 is equipped with a motorized Z-axis for effortless height adjustment. With its advanced auto-focus capability, you can experience fast and reliable measurements — perfect precision every time.

Introducing the Struers DirectConnect motorized stage, with built-in encoders for high repeatability. Available in three sizes to fit your needs, it offers fast, accurate navigation over multiple samples and allows you to get more done. The cable-less design enhances durability and streamlines your setup.

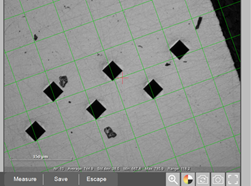

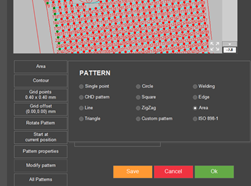

Enhance your sample orientation with our advanced grid functionality. Use the "Follow XY stage" feature to maintain a fixed grid aligned with absolute coordinates. Set indent distances, adjust point offsets in custom patterns, or align sample edges with ease. Perfect for precise measurements.

The hardness tester automatically stops operating in the event of a collision or any unexpected vibration or movements. This prevents indenters and lenses from being damaged and provides optimal operator safety.

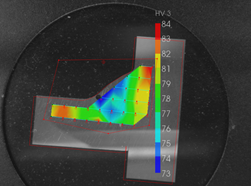

Several software modules are available to match particular applications. These include modules covering case hardness depth measurement (CHD), weld measurement, surface mapping, edge detection, and Kc fracture toughness calculation.

The optional overview camera makes it easy to position the test point series across a sample and execute it with a few mouse clicks. This feature ensures simplified execution and setup and is helpful when performing repetitive or high-volume measurements or weld testing.

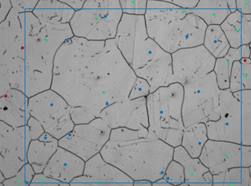

Enjoy higher resolution for finer features, perfect for technical papers and reports. Enhanced digital zoom means fewer objectives needed, saving you money. Combined with the DuraSoft-Met module, the DuraVista-40 doubles as a low magnification microscope for precise measurements on etched samples.

For measuring substrate hardness, layer thickness, grain size, or phases in limited lab space or needing fast evaluations in production, the DuraSoft-Met module is your solution. Save valuable time with its improved workflow, combining hardness testing and metallography analyses in one machine. With the DuraSoft-Met module, the DuraVista-40 doubles as a low magnification microscope for precise measurements on etched samples.

The DuraVista-80 models come with a motorized, eight-position angled turret that include a touch probe and a positioning laser, automatic illumination, auto focus & touch focus and automatic image evaluation as standard. The maximum sample height is up to 200 mm with manual stage, with a throat depth of 180 mm. The DuraVista-80 is operated via a 27-inch color touchscreen running on the powerful DuraSoft control software. Objective lenses, indenters and motorized stages are ordered separately. Load options range from 0.1 gf to 62.5 kg for all models.

A short and clear description that gives you an immediate overview to help you make the best choice of equipment.

• Capacity and performance specifications

• Dimensions and weight

• Electrical data

• Noice levels

• Safety

Get the full introduction, descriptive visuals, and key feature descriptions to help you qualify your choice of equipment.

• Explanatory fotos

• Key feature descriptions

• Technical Data Sheet

Get more insights and key feature descriptions to help you qualify your choice of equipment.

Learn about:

• Load ranges

• Key feature descriptions

• Expansion possibilities

"True structures require proper and correct applications. Different material properties require broad application knowledge. Struers application specialists are experts in optimizing preparation methods, because application knowledge is necessary to select the correct preparation solutions. Your material – our application solutions.”

Birgitte Nielsen

Application Specialist, Struers ApS

Don’t make do with what we say! Look for the truth in the experiences of the people who use our equipment and knowledge. We asked a few of our loyal customers to tell us what they think is most important about Struers.

With the Duramin-40, we can take before and after pictures easily, so we can see potential cracks before we start the tests – and analyze them more efficiently afterwards.Everllence Jesper Vejlø Carstensen Senior Research Engineer, M.Sc., Ph.D.

We are extremely satisfied with the highly skilled service delivered by Struers. They always meet our needs quickly and efficiently.BRP Powertrain GmbH & Co. KG (Austria) Herr Thomas Brunmair Supervisor Material Lab

Since adopting Struers equipment, we have made significant savings within our manufacturing process as a result of reduced manpower requirements and productivity improvements.Nissan Motor Manufacturing UK Ltd. John Smart Production Supervisor