TargetSystem facts

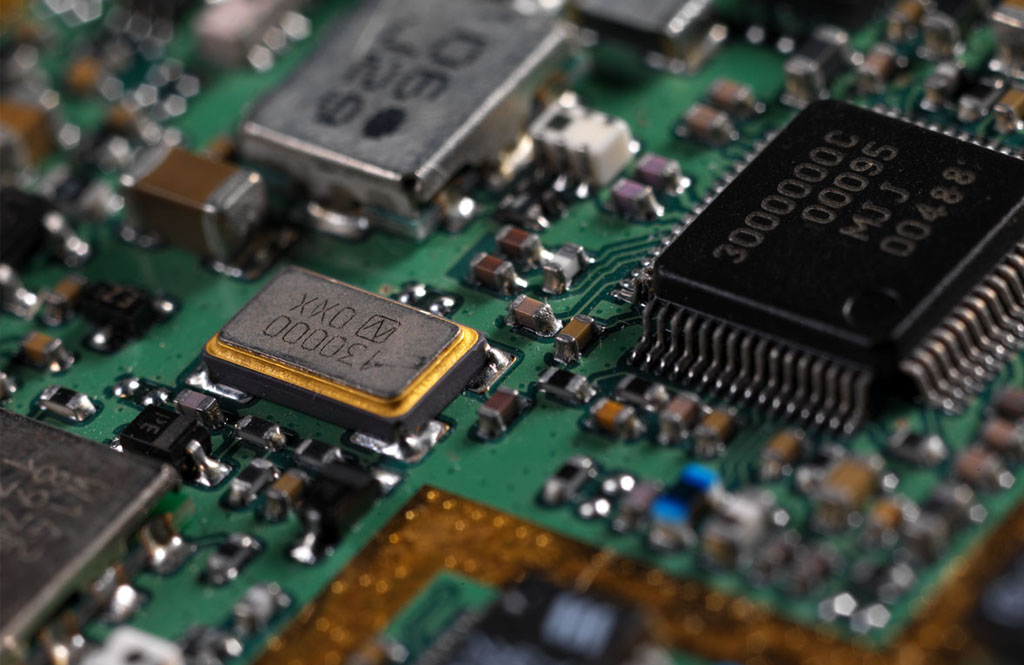

- Target preparation of microelectronic components

- Automatic reliable target preparation

- Analysis of visible and hidden targets

- Drastically reduced preparation time

- No dependency on operator skills

- Full reproducibility

- No need for costly abrasive films

TargetSystem is designed for target preparation of microelectronic components and delayering. It is the first failure analysis tool permitting real-time alignment and measurement of both visible and hidden targets, such as microvias and BGAs. System precision is an exceptional +/- 5.0 µm.

Short Preparation Times

An intelligent preparation system (IPS) automatically adapts the removal time and rate according to actual specimen properties and the grinding/polishing surface. This means fewer measurements and preparation times, down to less than 30 minutes.

Reproducibility

Automated processes make TargetSystem independent of operator skills, ensuring reproducibility regardless of the operator.

Low Operating Costs

TargetSystem can be used with any SiC paper, or any other consumable, and does not need costly abrasive films.

Case story: How Bosch Engineering Center Cluj increased Precision of Hidden-Target Preparation within 5 μm

KEY UNITS THAT ENABLE AUTOMATIC TARGET PREPARATION FOR BOTH VISIBLE AND HIDDEN TARGETS

-

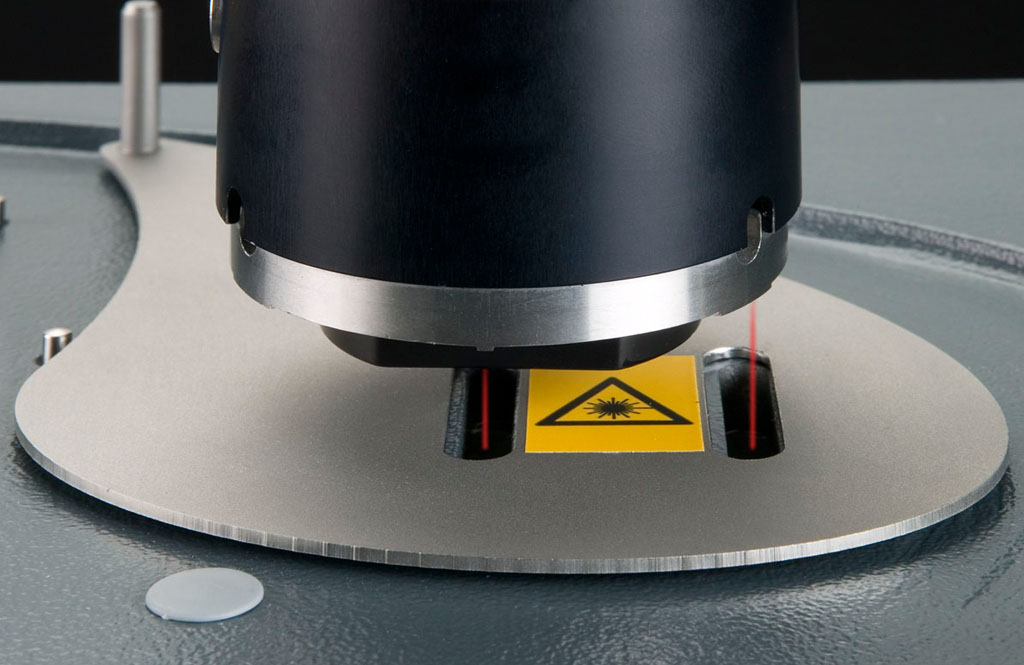

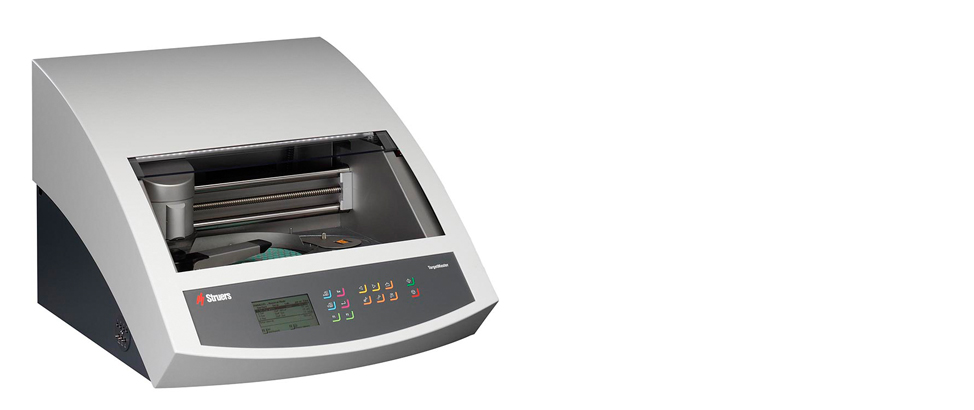

TargetMaster

The heart of the TargetSystem is the TargetMaster, a 200 mm micropolisher with a closed polishing chamber to safeguard both preparation quality and the operator. Removal at the initial preparation step(s) is controlled by an electronic measuring system, for a rapid approach to the target. A second, in-line laser measuring system handles the demanding polishing steps.

TargetMaster

-

TargetZ

TargetZ is used for aligning and measuring specimens with visible (external) targets. With a powerful vision system of up to 680x magnification and its 15" TFT monitor, TargetZ makes it a simple task to map and align minute targets.

TargetZ

-

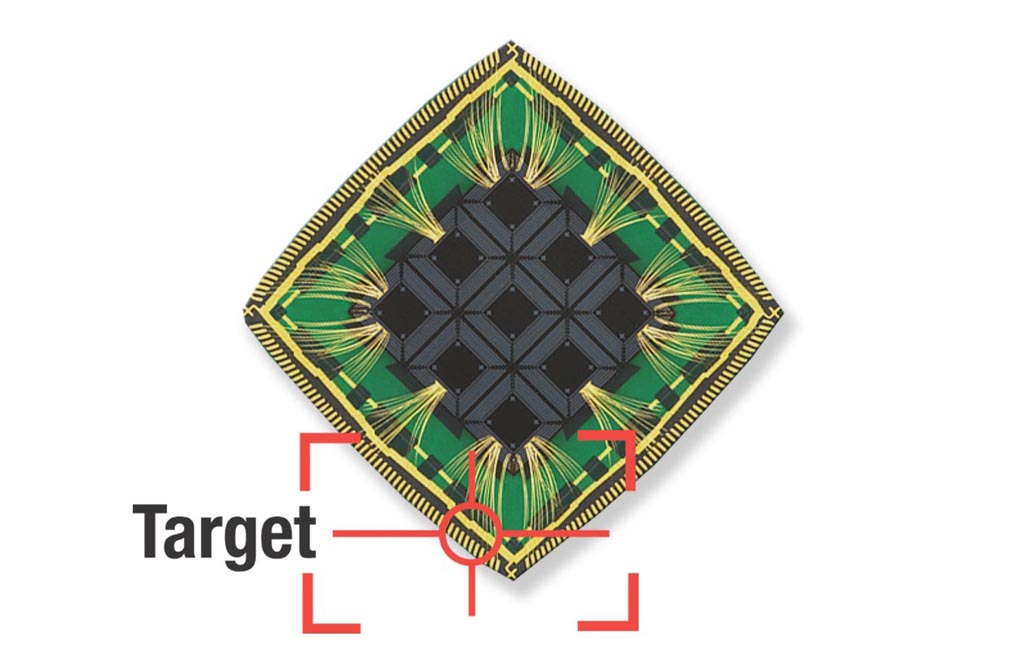

TargetX

TargetX is for hidden (internal) targets, and comprises a set-up station and a console. The set-up station is placed in the users x-ray (not included) and is operated from the external console, permitting real-time alignment and measuring.

TargetX

-

TargetDoser

TargetDoser is an automatic dosing station, providing preparation methods and process liquids to TargetMaster. TargetDoser comes with seven pumps and ten pre-programmed methods, and accommodates 200 user-defined methods.

TargetDoser

-

TargetGrip

TargetGrip is a tiltable specimen holder, dedicated to TargetMaster. It accommodates mounted samples up to 40 mm in diameter. Adapters are provided for larger specimens (TARIN), cross-sectioning (TARSC) and parallel polishing (TARPA), as well as a 40 mm to 25 mm adapter (TARAD), which serves as a SEM mount, as well.

TargetGrip

Facts

Model types

TargetSystem

200 mm micropolisher for automatic target preparation. Tiltable holder for 30 mm specimens and 200 mm MD-Disk included.

The dosing system is ordered separately.

Struers’ equipment is in conformity with the provisions of the applicable international directives and their appurtenant standards.

Struers’ products are subject to constant product development. Therefore, we reserve the right to introduce changes to our products without notice.

Technical Data

TargetSystem Technical Data Sheet

Struers Technical Data Sheets are designed to help you make the best choice of equipment for your particular purpose. You can find important information such as capacity and performance specifications, dimensions, weight, electrical data, noise levels, ambient conditions, and safety. In many cases you can also obtain an overview of accessories offering higher capacity and performance.

Download Technical Data SheetGrinding & Polishing consumables

-

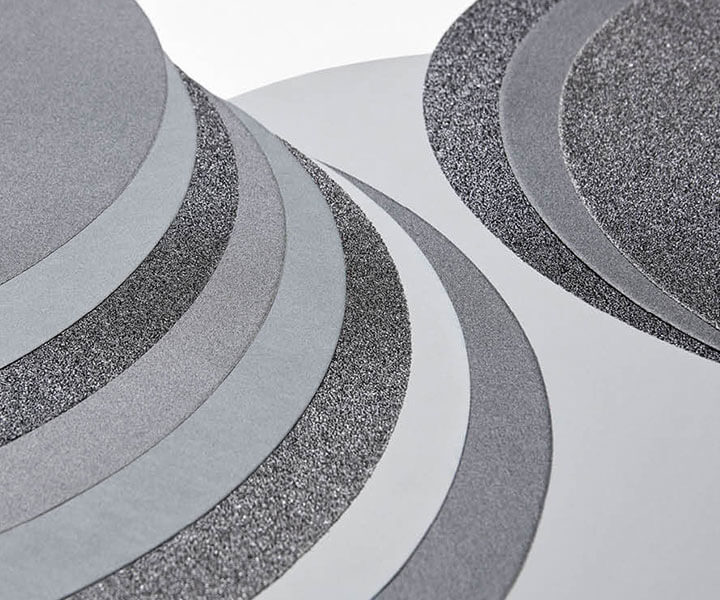

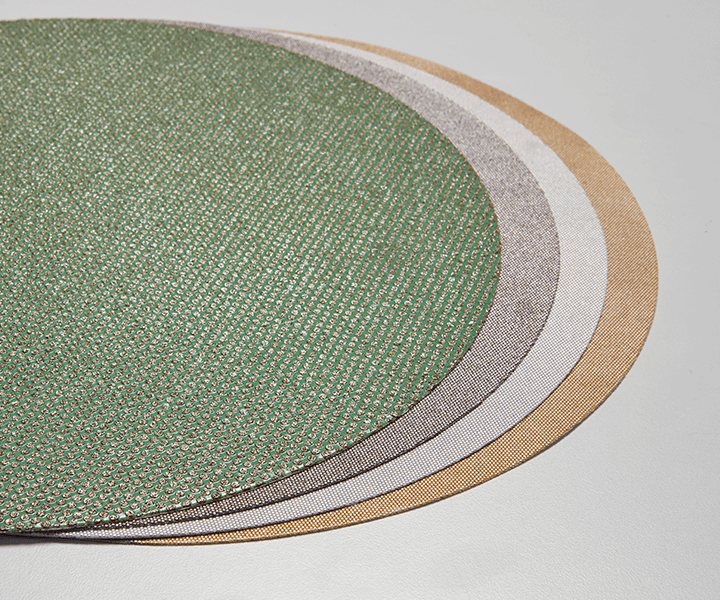

MD Grinding

For plane and fine grinding with virtually no artifacts

Read more Contact sales -

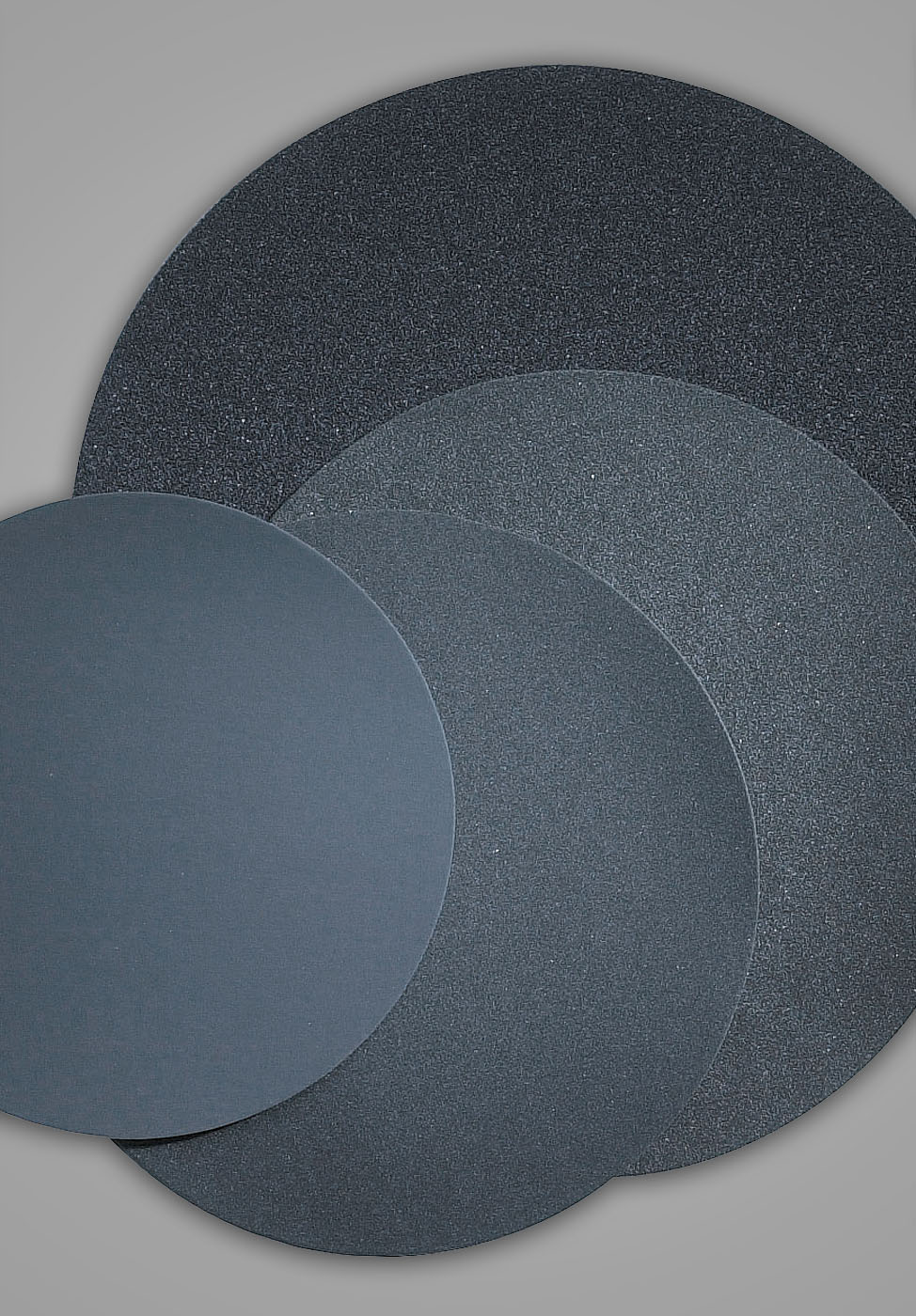

Silicon Carbide Foil and Paper

For plane and fine grinding

Read more Contact sales -

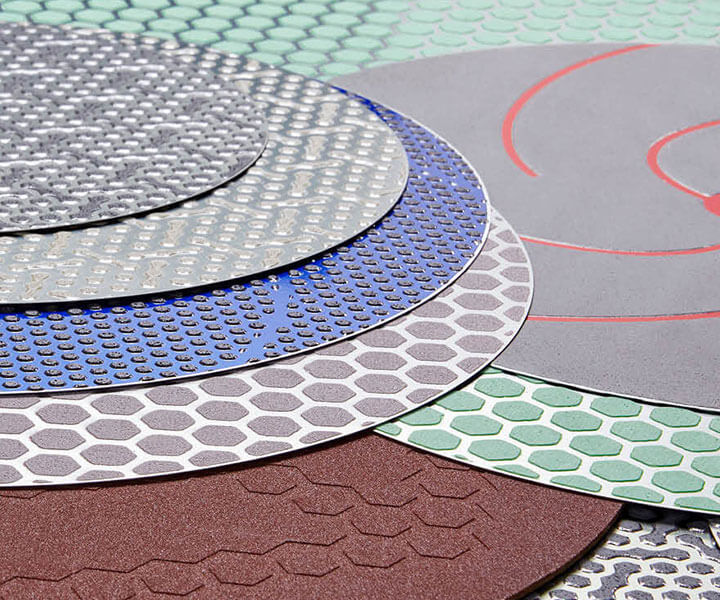

Diamond Pads

For plane and fine grinding of very hard materials

Read more Contact sales -

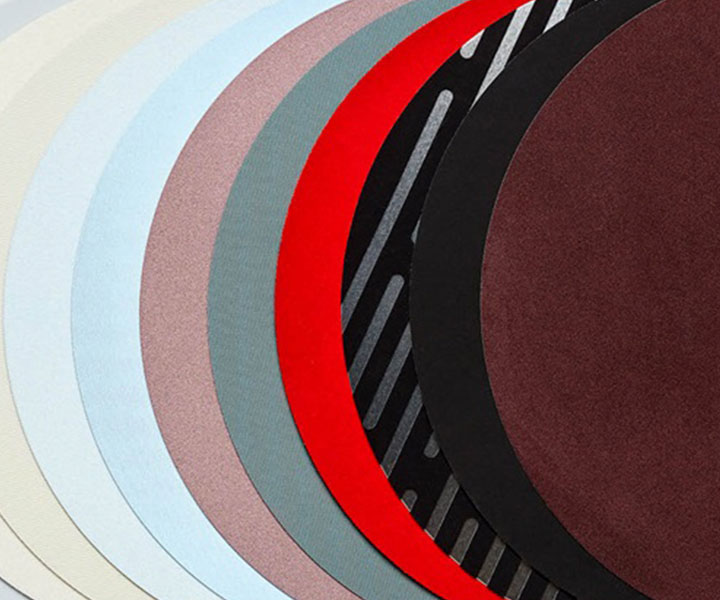

Polishing cloths

For any material and preparation goal

Read more Contact sales -

DiaPro

All-in-one diamond solution optimized for a specific polishing cloth

Read more Contact sales -

DiaDuo-2

All-in-one diamond solution

Read more Contact sales -

DP-Products

Diamond suspensions in a wide variety of grain sizes and formats

Read more Contact sales -

DP-Lubricants

For accurate cooling and lubrication while polishing

Read more Contact sales -

Oxide Polishing

When no scratches and deformation is required

Read more Contact sales -

+

-

−

Challenge

The automotive electronics division of Robert Bosch in Romania was looking to improve their cross-sectioning results of microelectronic boards. Their challenge was the preparation of tiny and hidden targets beneath the surface of a BGA (electronic component) without introducing deformation to the specimen.

Solution

In cooperation with the Struers application team, a new preparation process was developed for Robert Bosch SRL to minimize deformation. They chose TargetSystem, the automatic target preparation system for both visible and hidden targets, plus Accutom precision cutting machine.

Result

Robert Bosch achieved the following results with TargetSystem:

• Increased quality and precision of results by an impressive +/- 5 µm

• Polishing/grinding preparation time was reduced

• Reduction of consumables, saving time and money

Alexandru Siean, Failure Analysis Technician, Robert Bosch SRL – Bosch Engineering Center Cluj

Read the case storyCorrect preparation solutions

"True structures require proper and correct applications. Different material properties require broad application knowledge. Struers application specialists are experts in optimizing preparation methods, because application knowledge is necessary to select the correct preparation solutions. Your material – our application solutions.”

Birgitte Nielsen

Application Specialist, Struers ApS

MEET SOME OF OUR CUSTOMERS

Don’t make do with what we say! Look for the truth in the experiences of the people who use our equipment and knowledge. We asked a few of our loyal customers to tell us what they think is most important about Struers.

We have been using Struers equipment and consumables for almost 30 years and have benefitted enormously from their unparalleled service and applications support.John Crane UK Ltd. UK Bill Taylor Materials & Forensics Engineer

We are extremely satisfied with the highly skilled service delivered by Struers. They always meet our needs quickly and efficiently.BRP Powertrain GmbH & Co. KG (Austria) Herr Thomas Brunmair Supervisor Material Lab

Since adopting Struers equipment, we have made significant savings within our manufacturing process as a result of reduced manpower requirements and productivity improvements.Nissan Motor Manufacturing UK Ltd. John Smart Production Supervisor