Accutom facts

- High precision

- Shorter cutting time

- Higher productivity

- Perfect planeness

- Easy to learn and use

- 75-150 mm (3-6”) diameter cut-off wheel size

- 150 mm (6”) diameter cup wheel size (Accutom-100)

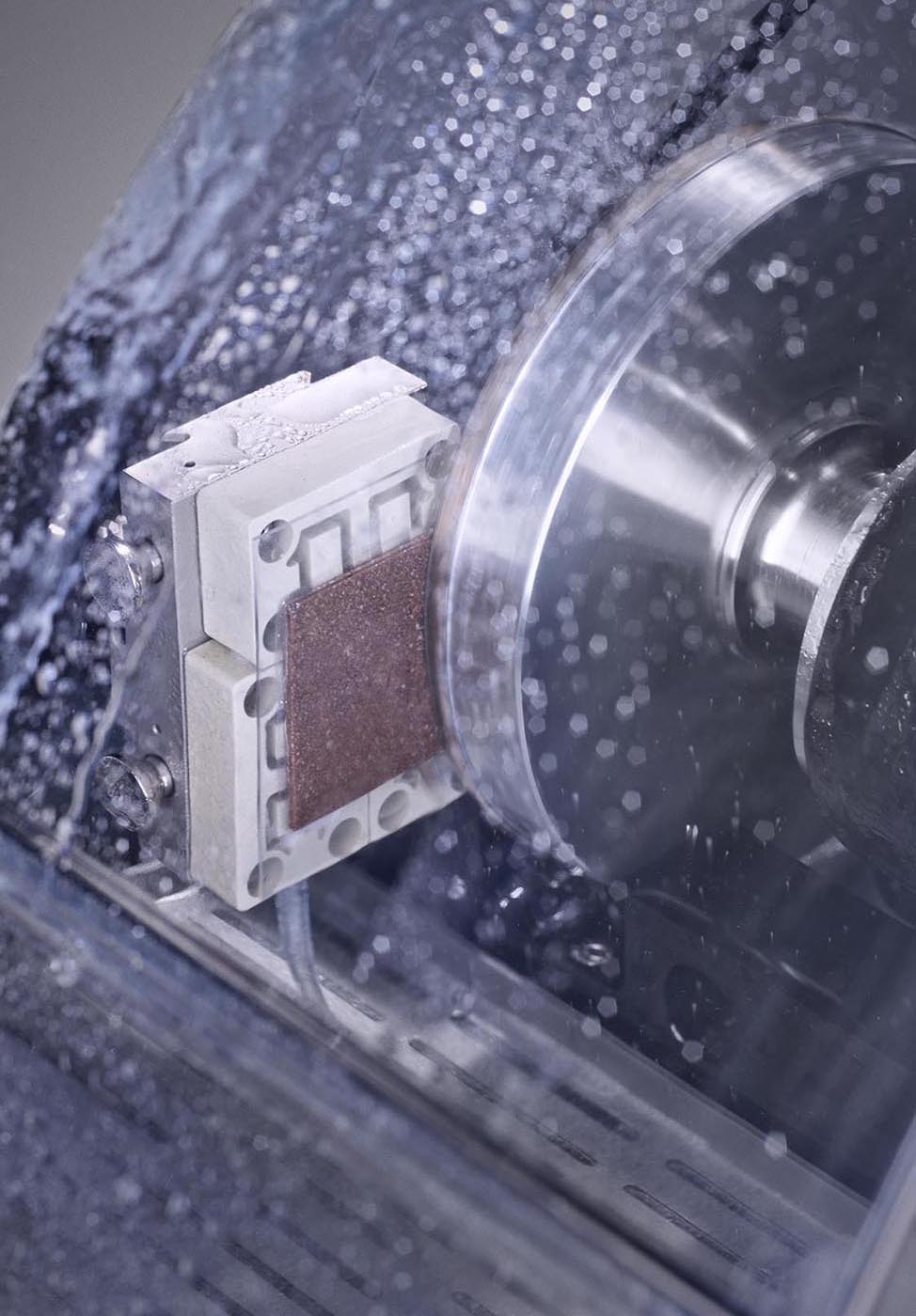

The redesigned Accutom cut-off machines from Struers are optimized for precision and ease of use to give the user a head start in the drive for perfect specimens. Packed with easy-to-use functions, they enable world-class cutting precision with a minimum of effort. The Accutom-100 includes a MultiCut function for extra productivity, and a grinding mode with multiple bi-directional sweeps between steps to ensure perfect planeness.

World-class precision

Positioning with fingertip precision is easy. The operating keys on the control panel move the specimen holder in the X-direction with 5.0 or 100 μm increments, and the cut-off/cup wheel motor in the Y-direction. Mounting the specimen holder directly on the X-movement arm ensures a high level of precision and parallelism.

Easy to learn and use

An intuitive user interface provides a clear overview of each method and related cut-off wheels. A smart turn/push knob enables fast selection of settings and large icons provide an easy-to-understand overview of functions.

Optimum preparation quality

Grinding mode is available on Accutom-100 and can be used for all types of material using multiple bi-directional sweeps between movements in the X-direction to ensure perfect planeness. Two grinding modes are available for accurate control of material removal to achieve the optimum preparation result.

Case story: How Bosch Engineering Center Cluj increased Precision of Hidden-Target Preparation within 5 μm

KEY FEATURES THAT ENABLE PRECISION GRINDING AND HIGHER PRODUCTIVITY

-

Versatility

World-class precision makes Accutom ideal for delicate applications such as teeth, otolith, microelectronic components, PCB, painted layers, minerals, and concrete.

Versatility

-

High precision and easy positioning

Positioning with fingertip precision is achieved using the convenient smart keys on the control panel to move the specimen holder in the X-direction with 5.0 or 100 µm increments and the cut-off/cup wheel motor in the Y-direction.

High precision and easy positioning

-

Intuitive user interface – easy to learn and use

An intuitive user interface provides a clear overview of each method and related cut-off wheels. A smart multifunction knob enables fast selection of settings and large icons provide an easy-to-understand overview of functions.

Intuitive user interface – easy to learn and use

-

Grinding mode with perfect planeness

Available in Accutom-100, grinding mode can be used for all types of material using multiple bi-directional sweeps between movements in the X-direction to ensure perfect planeness.

Grinding mode with perfect planeness

-

Rotation and oscillation for shorter cutting time

Rotation of the workpiece significantly reduces cutting time, e.g. for a tube or round workpiece, while oscillation prevents overheating when cutting hard materials.

Rotation and oscillation for shorter cutting time

-

MultiCut for extra productivity

The MultiCut mode boosts productivity by enabling cutting of up to ten identical or different slices in a single, automatic workflow. MultiCut is available on the Accutom-100.

MultiCut for extra productivity

-

Safety lock

Complies with the latest safety standards to ensure optimal safety for the operator.

Safety lock

-

Flexible LED light

Provides easy illumination of alignment and the machine interior when flushing.

Flexible LED light

-

Method Database

Enables input and retrieval of up to 100 cutting and grinding methods.

Method Database

-

Built-in flushing gun

Makes cleaning fast, easy, and effective.

Built-in flushing gun

-

Rotation/oscillation

Reduces cutting time and avoids overheating of hard materials

Rotation/oscillation

-

Built-in recirculation cooling unit

No extra tank required – capacity of 4.75 l.

Built-in recirculation cooling unit

Facts

Model types

Accutom is available in two variations. See specifications for details.

Accutom-10

Precision cut-off machine with variable speed (300 - 3,000 rpm). Variable automatic feed speed and motorized positioning system with digital readout. Built-in specimen holder rotation and oscillation. Three changeable cutting methods. Complete with recirculation cooling unit, flange set 50 mm dia. and tray for extra filter paper and collection of cut specimens. Specimen holders, cut-off wheels, and additive for cooling fluid are ordered separately.

Accutom-100

Precision cut-off and grinding machine with variable speed (300 - 5,000 rpm). Variable automatic feed speed and motorized positioning system with digital readout with MultiCut function. Built-in specimen holder rotation and oscillation and vacuum pump connection for vacuum check. Cut-off wheel, cup wheel and material database, and 100 optional changeable methods included. Complete with recirculation cooling unit, flange set 50 mm dia. and tray for extra filter paper and collection of cut specimens. Specimen holders, cut-off wheels, cup wheels, and additive for cooling fluid are ordered separately.

Struers’ equipment is in conformity with the provisions of the applicable international directives and their appurtenant standards.

Struers’ products are subject to constant product development. Therefore, we reserve the right to introduce changes to our products without notice.

Technical Data

Accutom-10/-100 Technical Data Sheet

Struers Technical Data Sheets are designed to help you make the best choice of equipment for your particular purpose. You can find important information such as capacity and performance specifications, dimensions, weight, electrical data, noise levels, ambient conditions, and safety. In many cases you can also obtain an overview of accessories offering higher capacity and performance.

Download technical data sheetGet Your Brochure for Accutom

Get the full introduction, descriptive visuals, and key feature descriptions to help you qualify your choice of equipment.

• Explanatory photos

• Key feature descriptions

• Technical Data Sheet

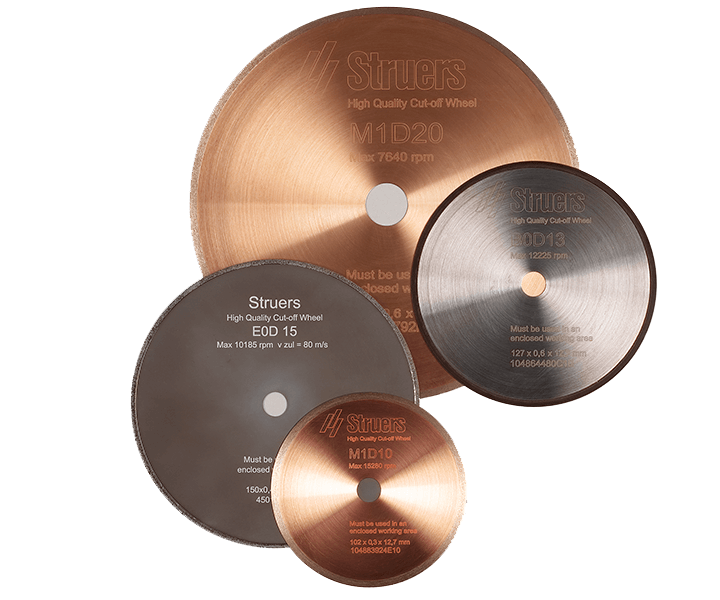

Cutting consumables

-

Abrasive cut-off wheels

Extremely hard ferrous metal (500 < HV < 1400).

Go to webshop Contact sales -

Abrasive cut-off wheels

Very hard ferrous metal (400 < HV < 800).

Go to webshop Contact sales -

Abrasive cut-off wheels

Hard Ferrous metal (275 < HV < 750).

Go to webshop Contact sales -

Abrasive cut-off wheels

Medium hard ferrous metal (200 < HV < 550).

Go to webshop Contact sales -

Abrasive cut-off wheels

Medium soft ferrous metal (100 < HV < 500).

Go to webshop Contact sales -

Abrasive cut-off wheels

Soft ferrous metal (75 < HV < 375).

Go to webshop Contact sales -

Diamond cut-off wheels

For materials with HV 500-2400.

Go to webshop Contact sales -

CBN cut-off wheels

For materials with HV 500-2400.

Go to webshop -

Additives for cutting

For recirculation, cooling and cleaning.

Go to webshop Contact sales -

+

-

−

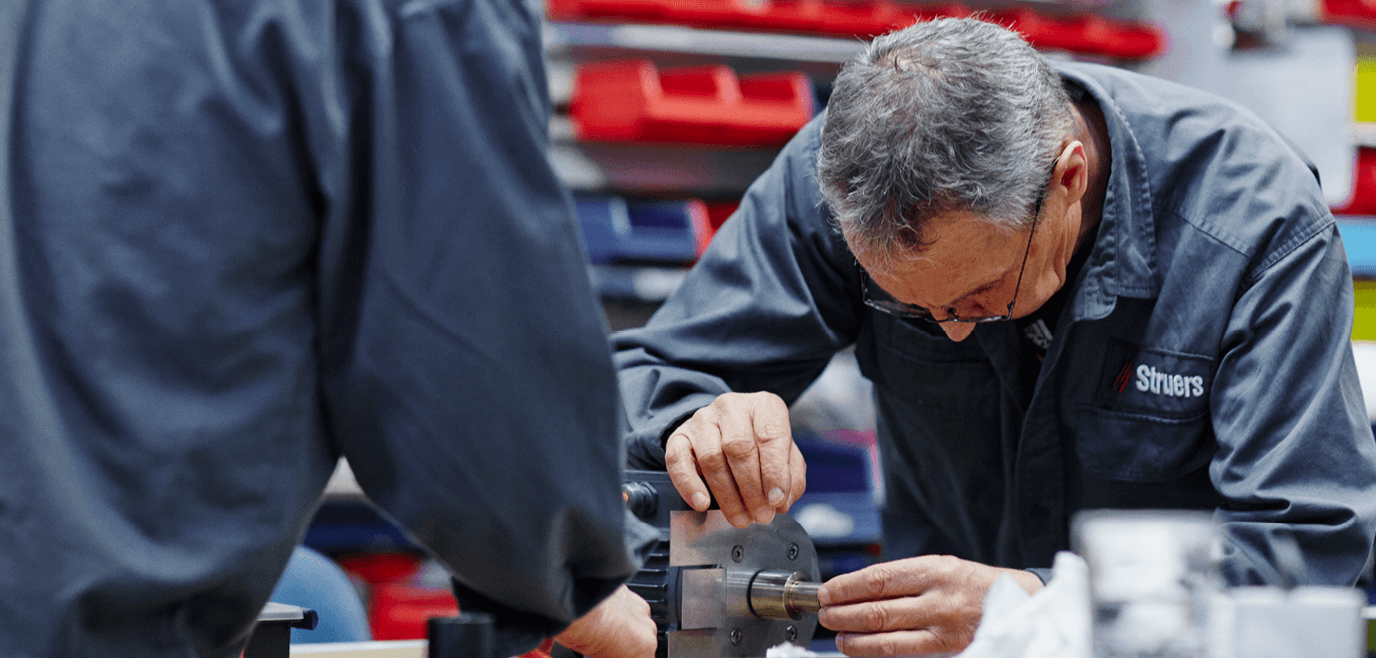

Correct preparation solutions

"True structures require proper and correct applications. Different material properties require broad application knowledge. Struers application specialists are experts in optimizing preparation methods, because application knowledge is necessary to select the correct preparation solutions. Your material – our application solutions.”

Birgitte Nielsen

Application Specialist, Struers ApS

MEET SOME OF OUR CUSTOMERS

Don’t make do with what we say! Look for the truth in the experiences of the people who use our equipment and knowledge. We asked a few of our loyal customers to tell us what they think is most important about Struers.

My relationship with Struers dates back over many years. The reason is their expert advice, good service, and their use of our application laboratory in the case of difficult questions that are best resolved on-site.WWU Münster, Institut für Planetologie Ursula Heitmann Mineral Specimen Preparer

Since adopting Struers equipment, we have made significant savings within our manufacturing process as a result of reduced manpower requirements and productivity improvements.Nissan Motor Manufacturing UK Ltd. John Smart Production Supervisor

We have been using Struers equipment and consumables for almost 30 years and have benefitted enormously from their unparalleled service and applications support.John Crane UK Ltd. UK Bill Taylor Materials & Forensics Engineer